Picture your supply chain making decisions before challenges appear, reacting to changes with precision, and reducing friction at every turn.

AI-automation is the driving force behind this new agility, giving businesses a smarter way to boost performance and stay one step ahead.

Find out how adopting these tools can transform outdated processes into seamless, forward-thinking supply chain operations that consistently deliver for your customers.

Key Takeaways

Why Supply Chain Decisions Demand AI Automation

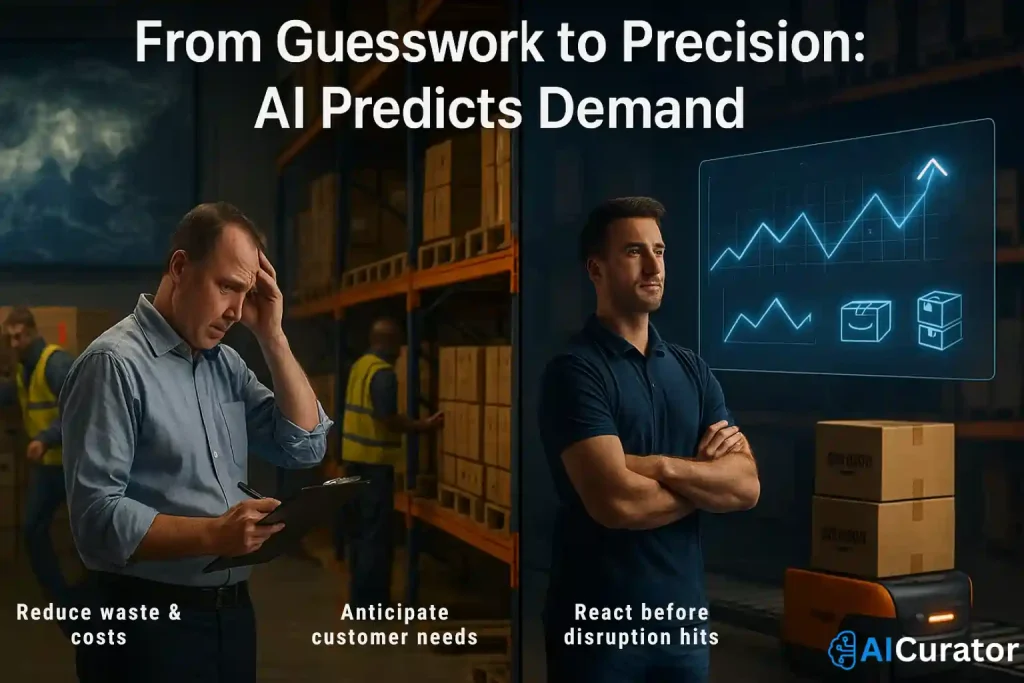

Complex, global networks are tough to manage with spreadsheets or guesswork. AI-automation removes blind spots by:

Big brands—Amazon, Nike, Siemens—have embraced AI-powered planning to stay nimble and competitive. Even smaller logistics players now access similar tech through cloud-based platforms.

2026 Data Snapshot: AI’s Impact on Supply Chains

| Metric | 2025-2026 Value |

|---|---|

| AI in supply chain market size (2024) | $7.15B–$20.1B |

| Projected size by 2034 | $192.5B |

| Average cost reduction (AI-driven) | 15% logistics, 35% inventory |

| AI adoption rate by 2026 | 38% of businesses |

| Defect reduction from AI quality control | 18% |

| Faster planning (case: Microsoft) | 4 days → 30 mins |

| Operating costs cut with AI | Up to 50% |

| Stockouts reduced | Up to 96% |

How AI Automation Optimises Supply Chain Decisions

1. Predictive Analytics and Demand Forecasting

Machine learning models crunch past sales, seasonality, weather, and economic signals—spotting patterns invisible to the human eye. This:

Amazon’s algorithms, for example, predicted demand for 400M+ daily items on Cyber Monday, slashing lead times for billions of shipments.

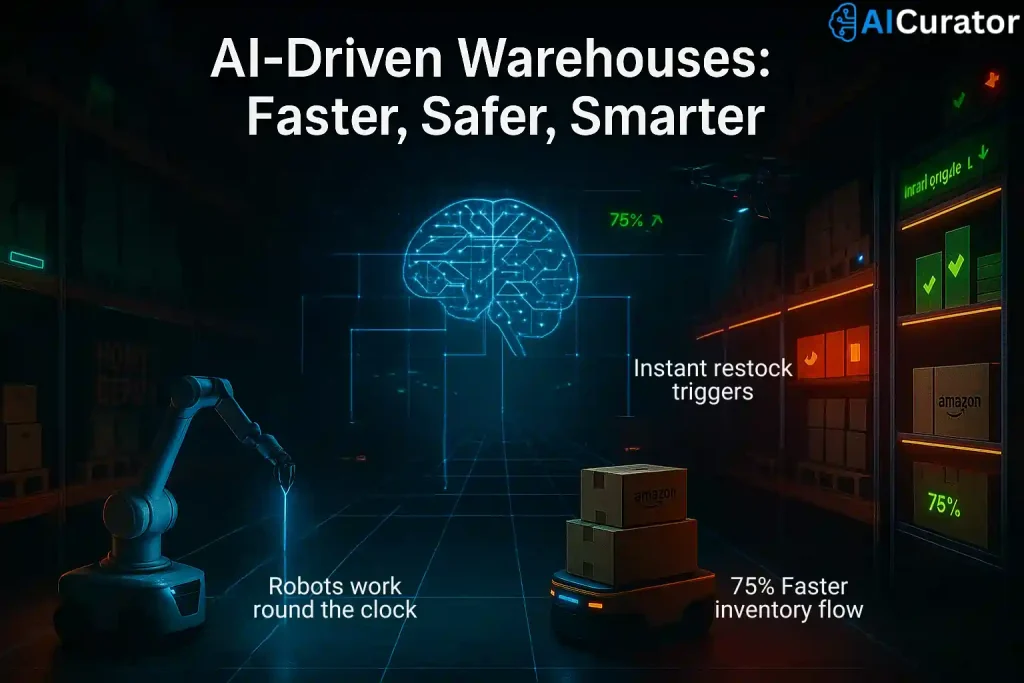

2. Automated Inventory and Warehouse Management

AI-powered robots pick, pack, and scan goods 24/7. Real-time AI monitors inventory, triggers automatic reorders, and spots bottlenecks long before they hit customers.

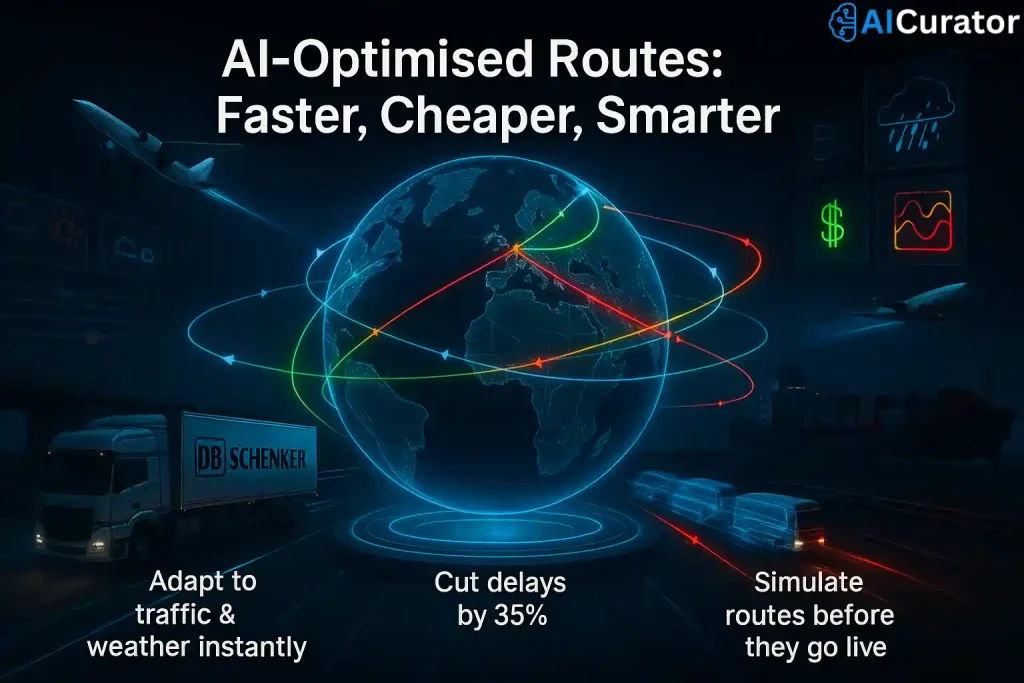

3. Smart Logistics & Route Optimisation

AI analyses millions of routes, weather, fuel prices, and traffic in real time to assign the fastest and cheapest delivery paths. Touchless planning means planned shipments adjust instantly to real-world changes.

4. Supplier Management and Risk Mitigation

AI reviews supplier histories, compliance notes, and emerging risks (from news or global events). Automated tools negotiate, create orders, and reject unreliable suppliers.

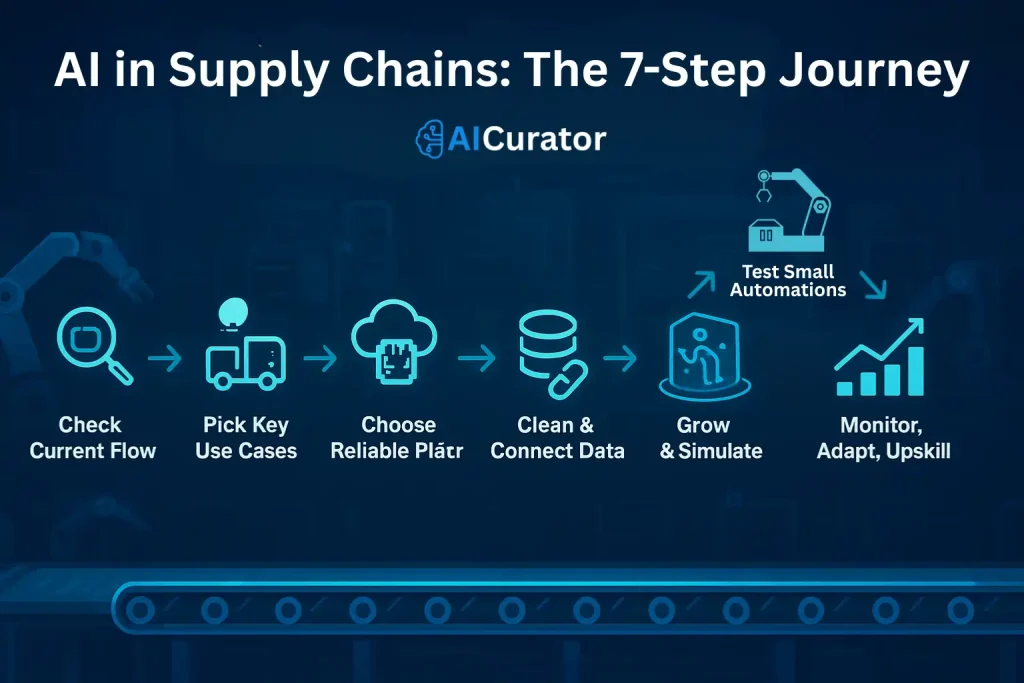

Step-By-Step Guide: Deploying AI Automation in Supply Chain Decisions

Step 1: Audit Your Current Supply Chain

Step 2: Prioritise Automation Use Cases

Step 3: Choose Trusted AI Platforms

Step 4: Ensure Data Quality & Integrations

Step 5: Start Small with Pilot Projects

Step 6: Scale Up Automation

Step 7: Monitor, Optimise, and Upskill Teams

Real-World Examples Inspiring Supply Chain Leaders

The Road Ahead

Smart supply chains built on AI-automation aren’t just the future—they are now the backbone of efficient, cost-saving operations. Teams gain speed and resilience, inventory headaches shrink, delays plummet, and decision-makers focus on strategic growth. Adopt AI tools methodically, integrating them step-by-step, and let the numbers do the talking.

By elevating decision quality and boosting operational agility, AI-driven automation delivers a clear edge as global supply chains get more complex.